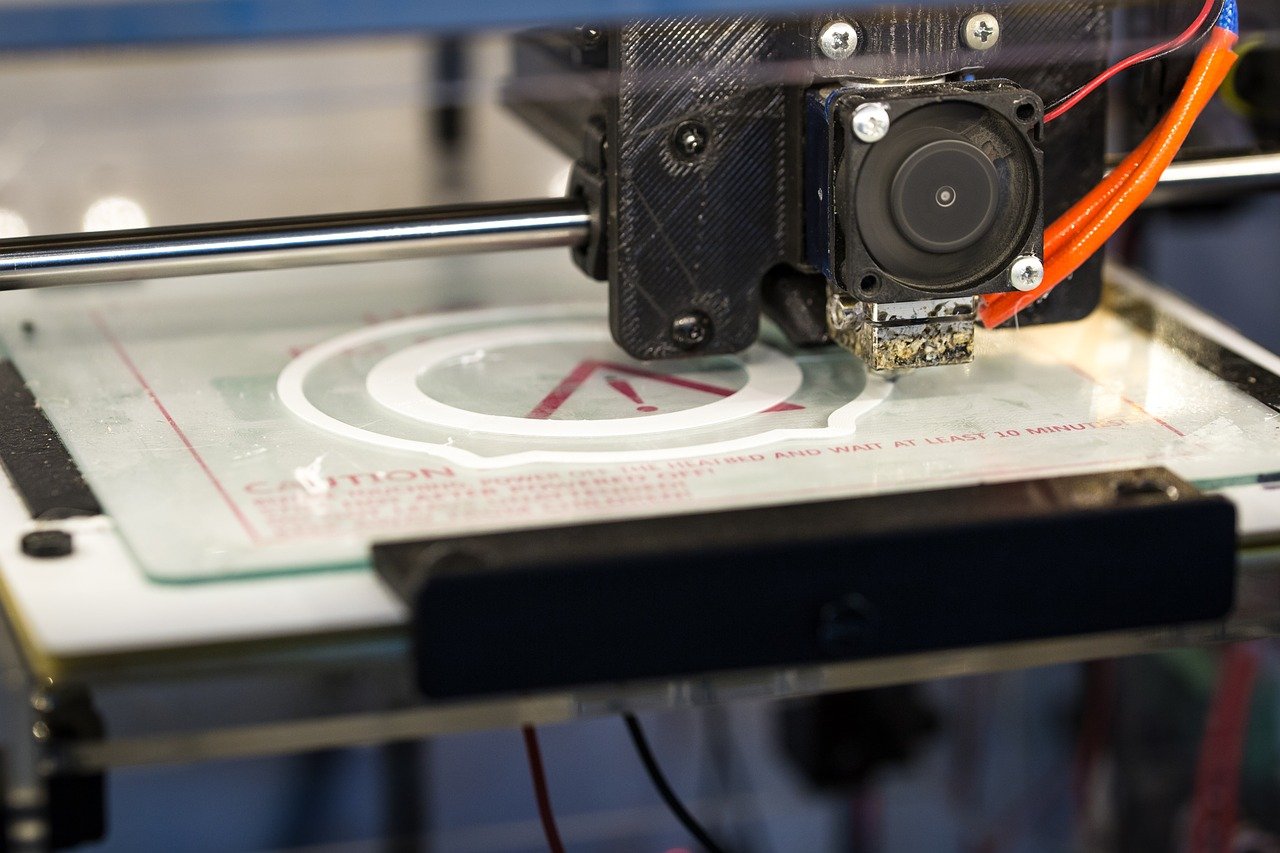

At a time when a 3D printing service can have your prototypes back to you in 24 hours, coupled with a growing influence of 3D printing in food innovation, medical device development and construction advancement, we look at how the land lies in 2021 with some of the most ‘out of the box’ designs you may now know about. Continue reading →

The last decade has revealed some of the most eye-popping 3D printed creations that were almost inconceivable less than a decade ago. From jet engines and jewelry to fashion, furniture and face masks, the number of objects created using additive manufacturing continues apace.

At time when a 3D printing service can have your prototypes back to you in 24 hours, coupled with a growing influence of 3D printing in food innovation, medical device development and construction advancement, we look at how the land lies in 2021 with some of the most ‘out of the box’ designs you may now know about.

First up is the triple record-breaking 3D printed 3Dirigo boat. Using the world’s largest 3D printer, the world’s largest printed boat also became the world’s largest printed object! An incredible 25 feet long and weighing around 5,000 pounds, the boat was built by the Ingersoll Machine Tool and officially unveiled by the University of Maine in 2019. Boats aren’t the only water bound objects that have been 3D printed either. Taking 42 days to print, full-size Kayak was created using a home printer, the brainchild of 3D printing engineer, Jim Smith.

Prompted by low levels of suitable organ donors the world over, in 2020, NASA Astronaut, Andrew Morgan and colleague, Christina Koch conducted experiments on board the International Space Station to create living tissue using bio-ink and a 3D printer. Outlining the value of the experiments, Morgan says that when you are 3D printing normally, tissue culture can collapse in gravity, but these effects do not occur in a micro-gravity environment.

This isn’t the only example of growing tissues in space. In June 2021, NASA announced two winners in its Vascular Tissue Challenge, a competition to make human organ tissue in-vitro in order to advance research on long-duration missions, as well as on Earth. The two winning teams used 3D printing to create liver tissue, one of the most complex organ tissues to replicate.

3D printing systems have also been helping to create brain tissue from human cells. The tiny 3D printed 4 – 6 cm device – a ‘microfluidic bioreactor’ – allows researchers to see brain organoids growing up to seven-day periods, meaning they can potentially examine more clearly how brains could react to different medications. According to Ikram Khan who wrote about the study, the costs of design are lower than other methods like using a petri dish or spin bioreactor. With these methods, contamination is avoided by sealing the dishes shut, which means cells usually die as it is not possible to add in nutrients. The 3D printed chip, however, allows for tubes and drug injection channels and provides greater visibility and observation.

The world of 3D printed medical devices is also expanding with the introduction of a 3D printed medical cast named the Osteoid. The prototype is aimed at improving the healing period for people who have suffered broken limbs by making the process more comfortable and reducing the amount of healing time. The Osteoid is designed to remove uncomfortable itching sensations and reduce weight and other limitations patients have with conventional casts. Incorporating ventilation holes, the device makes way for LIPUS – a low intensity pulsed ultrasound bone stimulator system which can be used for daily 20-minute periods to improve the healing rate.

That’s right. It’s now possible to 3D print your own face. Using 3D scanning, you can actually do this yourself, using your own device and special software. However, if you prefer to buy, you can purchase one from Japanese company, Kamenya Omote. The faces are uncannily similar, although they do not have moving eyes or lips. For sale since Spring 2021, there has been a high demand so far reported. Shop owner, Shuhei Okawara, says their main customers are creators for film and theatre, as well as some artists.

Not to be left out of the 3D printing revolution is the world of music. Responsible for creating a 3D printed Atom bass guitar using Selective Laser Sintering, Olaf Diegel, in charge of Creative Design and Additive Manufacturing at the University of Auckland has now launched the eye-catching, custom made Xenomorph Alien Themed Guitar. If it’s violin you appreciate then you simply have to take a look at the 2-string piezoelectric violin. Although it was initially created in 2015 by MONAD Studio, it’s still manages the element of visualise surprise in 2021. Finally, one of the latest instruments that’s been 3D printed is a new type of Cello. Created by MyCello, the creators have sought not to replicate existing models but to combine the best of both electric and classic cellos to bring greater personalization, shape and sound for musicians.

Whether it’s increasing traffic, boosting credibility, targeting local customers, or gaining a competitive edge, the…

By analyzing streaming data, social media engagement, and other metrics, A&R teams can discover emerging…

PDF document translation has long faced unique technical challenges, with traditional translation methods often struggling…

Atlys provides complete paperwork management to let you create lasting vacation experiences without worries about…

This article explains how candidate screening solutions work, their key features, and how businesses can…

Building lasting influence as a brand or business involves consistently producing good content, meaningful engagement…