There’s this undercurrent of global culture that praises the movers and shakers of the world. People look to Jeff Bezos and Elon Musk. They look to the super-elite. The reality is nothing gets done without the skills and the knowledge of the people on the ground. The pipes don’t work, the lights don’t flicker, and the structure fails without the men and women who dedicate their lives to their craft.

One such craft is metalworking. The ability to conceptualize, form, shape, and use the forged pieces of molten Earth as an end product for something bigger is, without a doubt, the core of our modern world. The ore and its supply ushered in the technological age. Without it, we’re centuries behind. Metalwork is, to this day, extremely important. It’s one of those professions that will not depreciate. It doesn’t matter if you’re a lifelong professional or a new hire, there’s always something new you can learn. If you’re looking to expand your knowledge or hone your skills, metalworking online education is a great option or see below for a few effective tips.

Brush Up On Maintenance

You may know the machines you work with like the back of your hand. That doesn’t mean you shouldn’t brush up on maintenance and care. When you put your nose to the grindstone and get the tasks done, you invariably put some wear and tear on the tools that you’re working with. Since we’re not in an iron forge with a hammer and a kiln, it’s important to keep up with parts, too. It’s all well and good until we need to turn and mill metal parts on short notice. General upkeep and familiarity are good. It’s part of proper quality assurance. So to acquainted, or reacquainted, with your machines. It does not hurt to do a once-over read on the manual. It may be boring, but it’s a good idea. Check the parts and maintenance logs. Make sure that you can put out the best work with the best conditions you can facilitate.

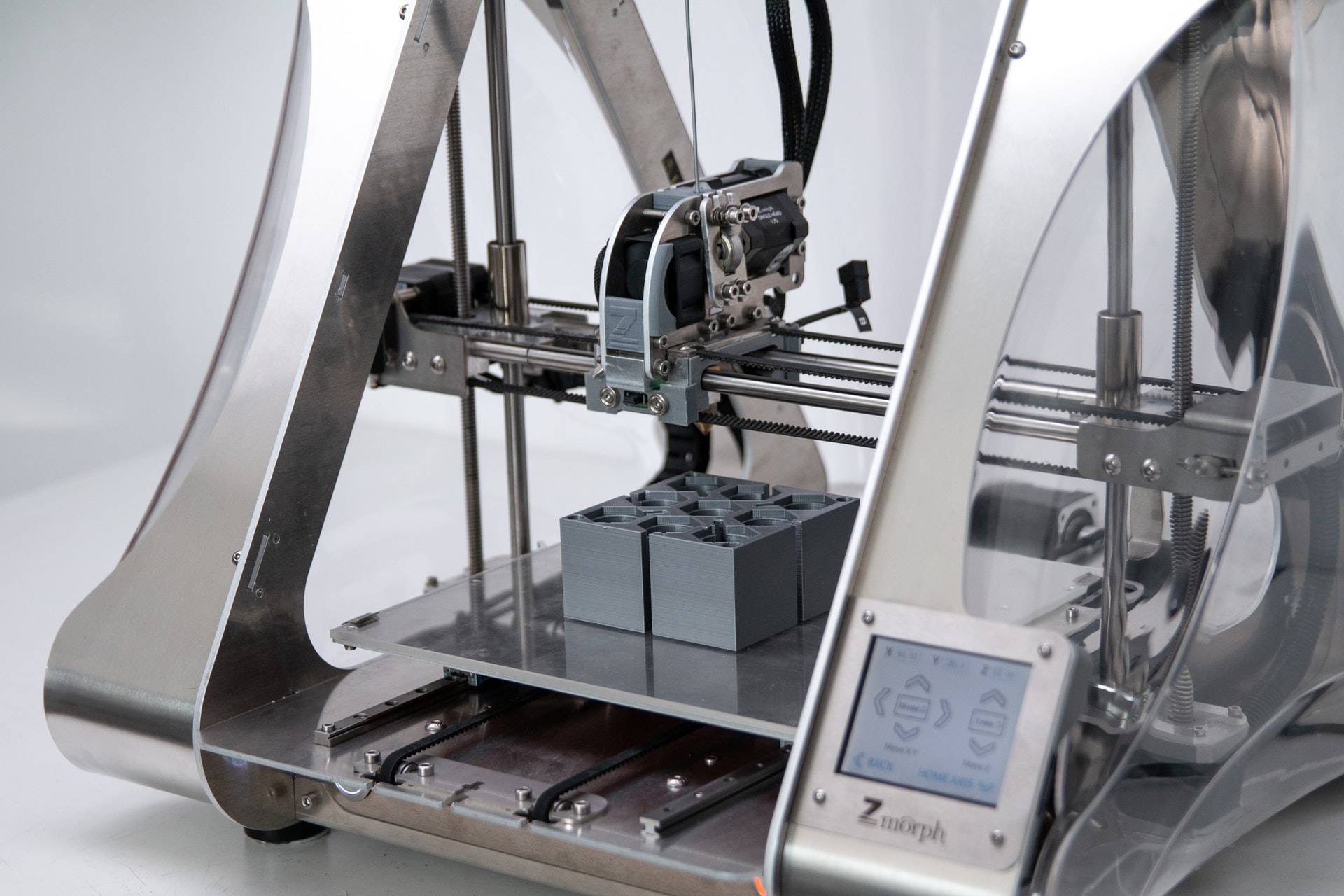

Adopt New Technologies

Adopting new technologies is another way to get better at metalworking. Fabricating is what makes modern tech move forward. There is no new model or cool product without fabricating. But what does improve is the techniques and the technologies used. Don’t be the only person stuck to old ways of thinking. Adapt, just like in any other industry. If there’s a means that completely contradicts your process, be open to letting some of that in. If there’s a detail you’ve noticed impedes on production, cut it out. The dirty secret is that there’s a lot of room for improvement in a lot of manufacturing and fabricating. Most professionals are set in their ways and avoid change. The ones that do ultimately get better, more confident, and attract better business.

Stay Efficient

People fawn over the lean/6sigma model of manufacturing. Yes, it’s important to keep things down to a predictable and quality assured science. But the belt thing is pretty odd. It reeks of Silicon Valley babble. That’s not to say the principles should not be followed. They absolutely can. But there are ways you can adopt them without the terminology. Simply put, you should know what the client is looking for and strive to get it done as simply as possible with virtually no waste. What’s the biggest thing clients are looking for these days? Lower cost and minimal lead time. How does one achieve that? Shorten setups. When you’re setting up, you need to have the software and the tooling to get things done as quickly as possible. Quick-change tooling on a press brake and turret punches, for example, can be outfitted with software that allows one to maintain precision—even in beginners. In terms of being a “better” metalworker, it will certainly seem like that to your clients.

Keep In Touch With The Old

Even with the advancements in technology, there is value in the older ways. There is so much to be learned when you do things with a more manual approach. Semi-automated means and less detailed software can be used on projects and jobs that don’t have the same sense of urgency as the others. Keep yourself knowledgeable the same way a doctor keeps a clinical eye. Don’t rely too heavily on new tech. Use them. Assure your clients you have them. But when push comes to shove, you should be able to work under the harshest conditions. That means without the new bells and whistles.

Getting better at metalworking is part of an ongoing pursuit of excellence in the field. It’s part of being a better worker in general. If you apply the principles above and keep these words in mind, there’s no doubt you’ll improve. Stay strong. Stay hungry.