For many years, metallic and plastic objects were often cut from larger stock pieces of material or molded. Throughout the 20thCentury, however, the idea that something could be constructed from zero by simply adding more material started to develop. This, in time, became known as 3D printing. Fast forward to the modern-day and suddenly 3D printers are available on the market for everyone. The problem then becomes, how do you know which type of 3D printer to buy? With such new technology, it can be really hard to know what you are looking for. In this article, we will discuss some of the most important things you need to know when choosing a 3D printer.

Types of 3D Printing Technology

There are no less than 9 different technologies developed for 3D printing. Printing Atom’s review on the best printers has all types of 3D printing technology listed, however, we are just going to briefly explain the most common 3 types. These are:

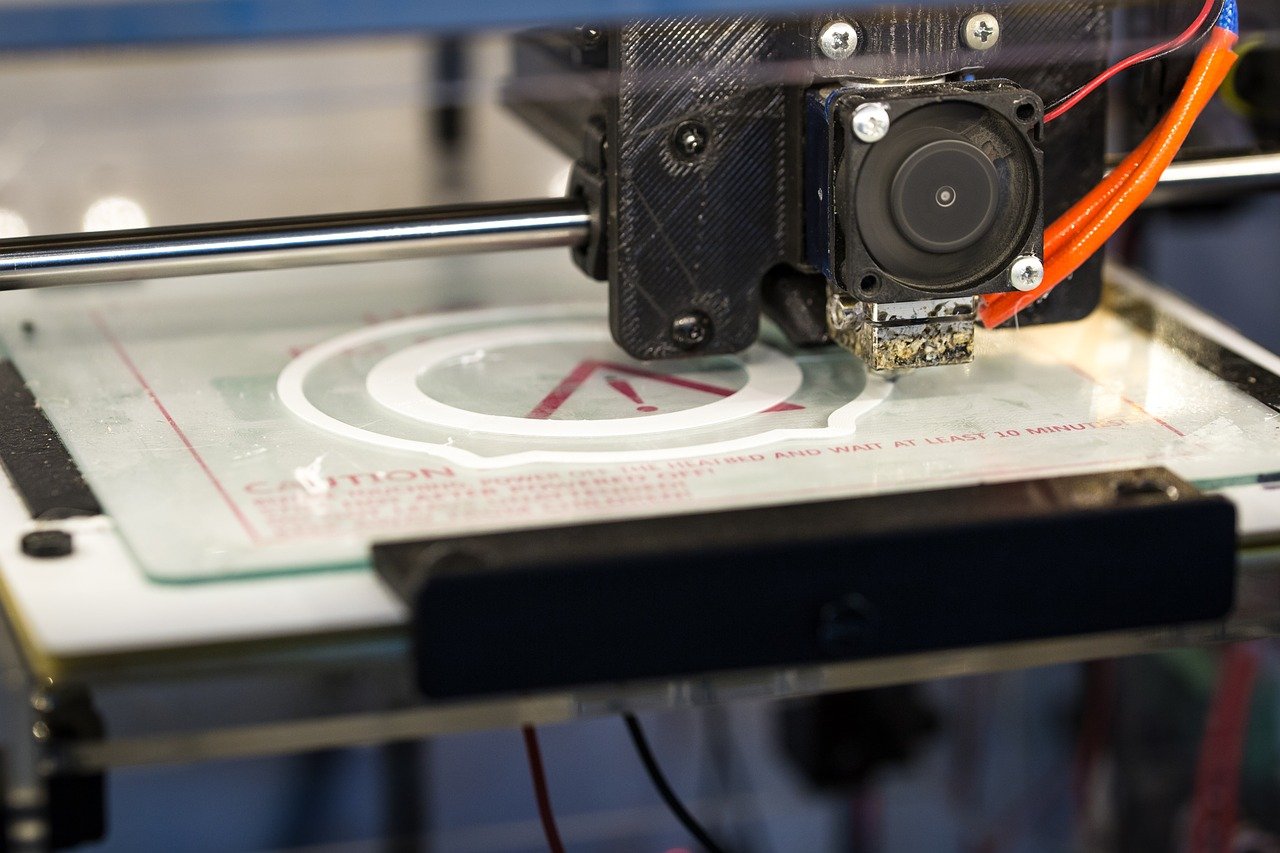

FDM – Fused Deposition Modeling

Fused deposition modelling (FDM) is very commonly used in private homes for 3D printing with plastic. It is sometimes known as fused filament fabrication (FFF) due to the way the process works. This kind of 3D printer works by pushing a plastic filament layer-by-layer onto a build platform. Choosing a 3D printer for you depends on what type of work you will be producing as well as how much of it. This means it is very quick and cheap but can result in rough finishes and products that are not very strong.

SLA – Stereolithography

Stereolithography(SLA) is the original 3D printing process. It uses a laser beam controlled by a computer to draw layers of a designed part, usually creating the support structures first, before moving on to the part itself. The laser beam interacts with a liquid thermoset resin to create each layer of your design. Once one layer is complete, the platform shifts down a level and moves to apply the next layer of resin, repeating each layer until the full design is complete. It creates very detailed, strong, and smooth-surfaced finishes.

SLS – Selective Laser Sintering

Selective Laser Sintering (SLS) printers work slightly differently. By melting together two nylon-based powders into a solid plastic as they print, they create durable finishes. They fall somewhere in between SLA and FDM printers as far as finish goes as they create rougher finishes. But, what they may lack in finish, they make up for in durability and strength. These are great for prototyping designs and testing parts.

What Do You Want To Print?

So, now that you’ve understood a little about the three main types of desktop 3D printer, it’s time to figure out which suits you. The first and most important question is; do you know what you want to print? As you can see, there are positives and negatives to each. FDM is much faster but produces rougher and less durable products, while SLS and SLA take longer but increase in durability and finish.

If you plan on printing models or other non-functional parts, maybe FDM is the correct printing process for you. If you are planning on designing parts with more functional purposes, you’d have to consider a more robust 3D printing technology. Some printers will be better for large scale output You may find a different 3d printer for tabletop miniatures.

If you are simply a hobbyist, we recommend you stick to FDM for starters. Knowing what you want to print will inform most of your decision regarding 3D printers.

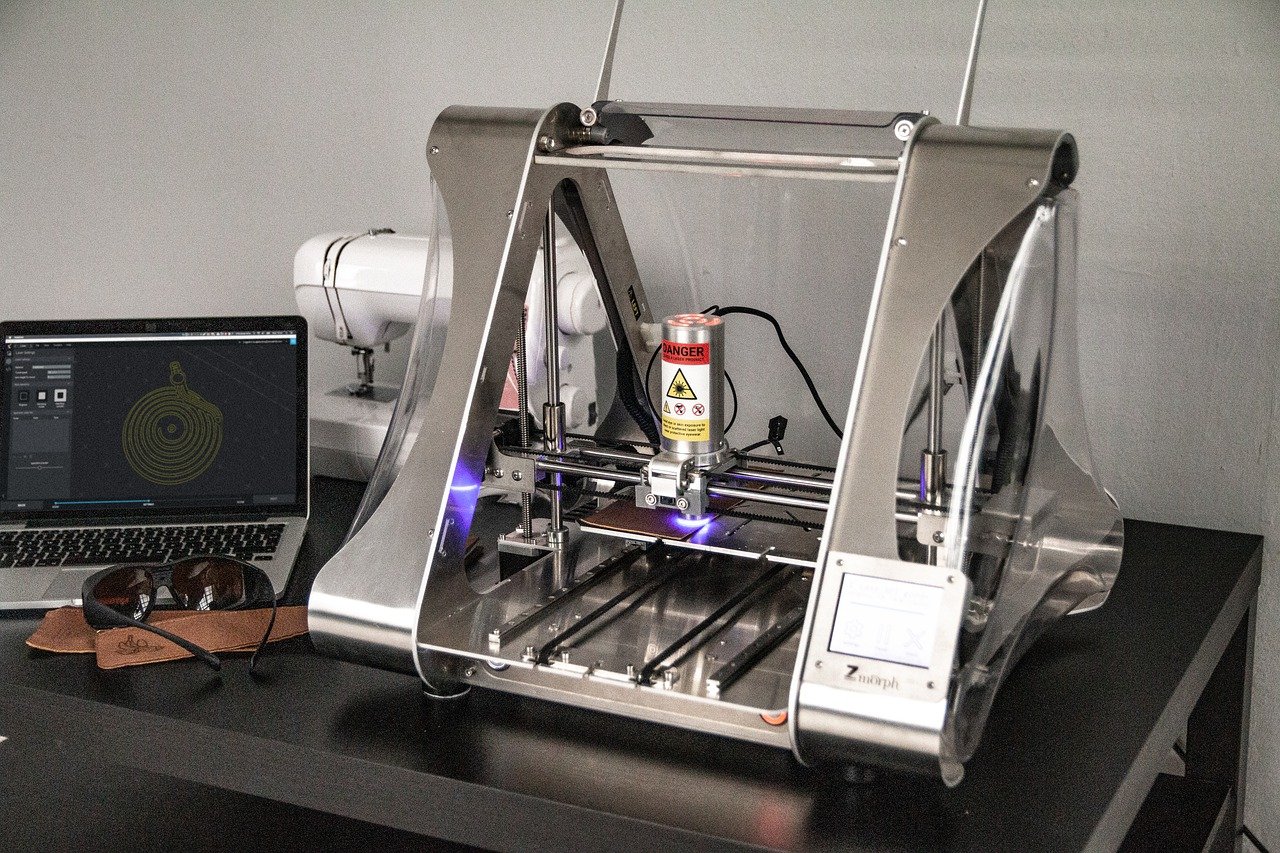

Open or Closed Frame?

As you may have guessed, 3D printers come in both open and enclosed designs. There are pros and cons to both which can have a big influence on what type you go for. Firstly, let’s discuss enclosed/closed frame printers. One big decider for home printers may be style, and many argue that enclosed printers look much neater than their open counterparts. They can also be much quieter and also produce slightly neater products due to the enclosure keeping drafts or dust out of the printing nozzle. On the flip side, many people prefer an open printer for a few reasons. Firstly, as it is open, you will be able to clearly see the printer’s progress and keep tabs on how your design is coming along. It is also arguably easier to keep clean and work on the printer as it is in action, as well as easier to perform maintenance and upgrades.

Price

It is also worth considering the price. FDM printers can start at a much cheaper value than SLA and SLS, with SLS occupying the highest price point on the scale. FDM and SLA both start quite affordable, so are generally considered good starter printers. Again, it truly depends on what you’d like to print, and how often.

You should now be armed with all the knowledge you need to decide which 3D printer to buy. It’s an enjoyable experience designing in 3D and watching your products come to life. We hope you find a printer you love.