Robotics’ transformative impact on your business could be a game changer. Once a luxury affordable only to large corporations, robotics technology has become more accessible and cost-effective, making it a viable tool for small businesses looking to innovate, enhance efficiency, and gain a competitive edge.

In this comprehensive guide, we’ll explore the myriad ways in which robotics can revolutionize small business operations.

Understanding the Basics of Robotics in Business

Robotics involves designing, constructing, operating, and using robots for automation. In business settings, robots can perform various tasks from assembly line jobs to complex analytics and customer service functions.

The integration of robotics can lead to significant enhancements in production speed, quality, and cost efficiency.

Using robotics means automating mundane tasks and transforming your business processes to increase productivity and enable innovation. The initial investment might seem daunting, but the long-term savings and potential for growth can far outweigh the upfront costs.

Redefining Productivity and Efficiency

Incorporating robotics into your operations can dramatically enhance productivity. Robots excel in performing repetitive and time-consuming tasks with unmatched speed and precision.

This capability allows you to reallocate human resources to more strategic, creative, and customer-focused roles, enhancing job satisfaction.

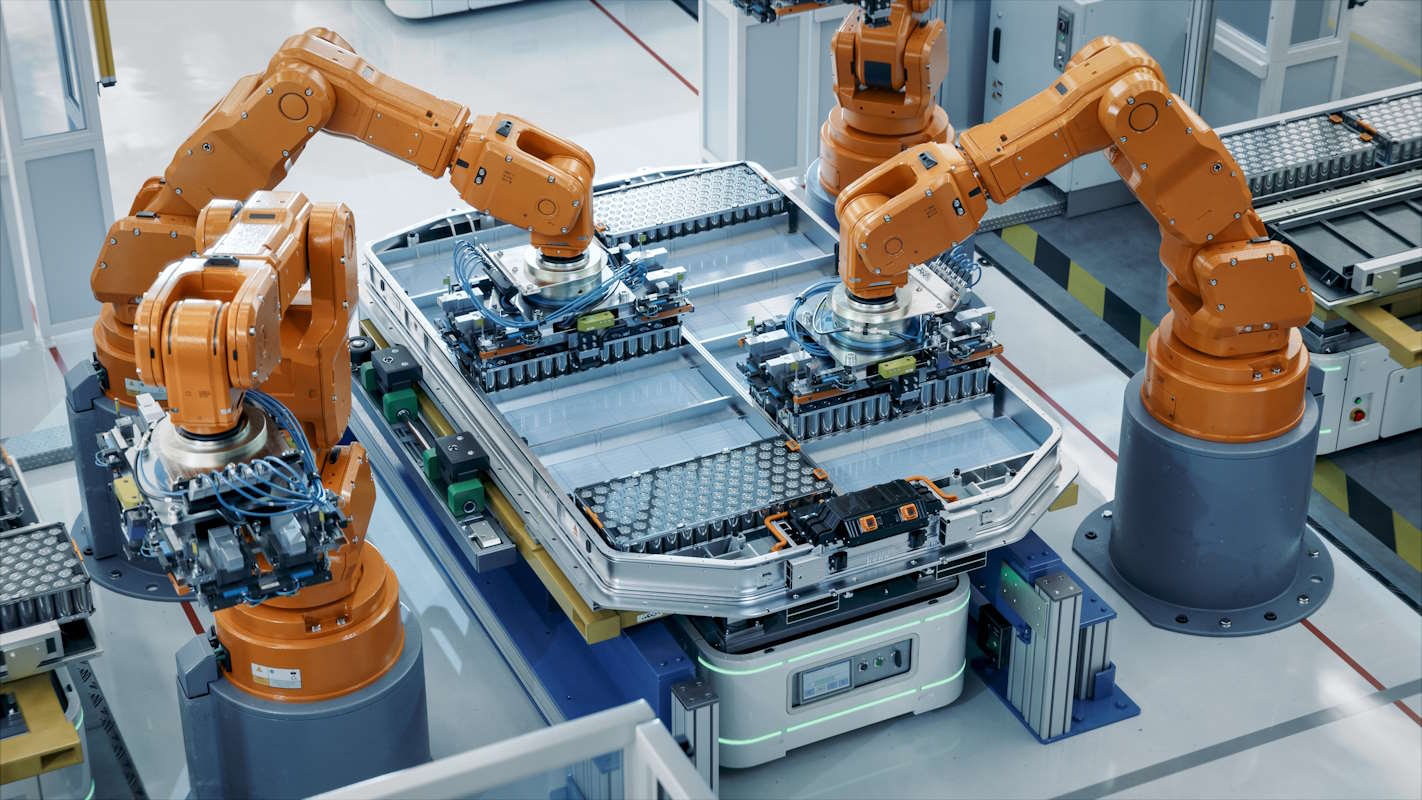

Consider the example of a small manufacturing firm implementing robotic arms on their production lines. These robots can operate 24/7 without fatigue, producing goods at a consistent quality level that few human workers can match.

This means faster production times, reduced human error, and a significant increase in output.

Quality Improvement and Customer Satisfaction

The precision of robotics technology also means improved quality and consistency in your products or services. Robots follow exact specifications without deviation, which is crucial in industries requiring high precision, such as electronics manufacturing or food processing.

Improved product quality can lead to higher customer satisfaction and fewer returns or complaints, enhancing your brand’s reputation in the market.

This reliability can become one of your brand’s selling points, attracting more customers to pay a premium for superior quality.

Cost Reduction and Investment Analysis

Understanding the cost implications and investment analysis is crucial before integrating robotics into your business. The cost of robotics has decreased significantly due to advancements in technology and increased production scales, making it more accessible for small businesses.

The return on investment (ROI) from robotics comes from several areas:

- Labor Cost Savings: Robots can perform the work of several people, especially in repetitive, high-volume tasks.

- Increased Production: Robots work faster and for longer hours, boosting your production capacity.

- Improved Quality: Reduced defects and consistent quality control lead to savings on return and rework costs.

Conducting a thorough cost-benefit analysis will help you understand the break-even point and long-term savings. Financing options such as leasing robots or buying second-hand can also make the transition more affordable.

Leveraging Robotics for Market Expansion

Robotics can also open new market opportunities for your business. With increased production capabilities and improved quality, you can expand into previously unattainable markets due to capacity or quality constraints.

Moreover, robotics can enable customization and personalization in production, which is highly valued in today’s market.

For example, a small business specializing in personalized gifts can use robots to engrave or assemble unique items based on customer specifications quickly and cost-effectively.

The Challenges of Implementing Robotics

While the benefits are significant, the challenges of integrating robotics into a small business environment must be addressed. These include:

- Technical Training and Adaptation: Your team will need training to work alongside robots and manage the new technology.

- Maintenance Costs: Robots require maintenance and repairs, which can be costly if not planned for adequately.

- Upfront Investment: The initial setup cost for robotics can be high, requiring careful financial planning and potentially external funding.

Addressing these challenges requires a strategic approach, including employee training programs, a maintenance schedule, and a solid financial plan to manage investment costs.

Revolutionizing Small Businesses with Robotics

The advantages of automation extend beyond simple labor replacement, offering opportunities for quality improvement, efficiency gains, and market expansion. Integrating robotics into your business may require a significant upfront investment and a shift in business processes, but the potential rewards make it a compelling choice for the future.

By carefully planning the integration and preparing for the challenges, you can set your business on a path to long-term success and sustainability in an increasingly automated world. Ultimately, robotics can help your business move towards a more innovative future.